This blog is the first in a series of posts in which the Great Recovery Programme will explore how to design a product with Circular Economy principles at the core of the brief. In today’s world, most things are designed without longevity in mind; worse, they are designed to be thrown away after a few years of use – through planned, technological or style obsolescence.

Design is a critical stage in any product lifecycle, especially in terms of end of life and sustainability, as 80% of the environmental impacts of the product will be decided during this stage.

The first step in the process of design is the brief generation. A brief focuses on the desired results of the design, and contains the problem statement (what is the problem we want to solve), the goals of the product (aims + objectives) and any constraints (budget, time, etc.)

Normally briefs contain one line, if anything, which describes the sustainability requirements of the product: “The product should be more environmentally friendly than the previous model” for instance. This is unless there is a law which obliges the company to act more thoroughly, for example the End of Life Vehicles (ELV) act in the automotive sector. In our case, the whole project will revolve around circularity, so our aims and objectives for the product will be based on the Four Design Models.

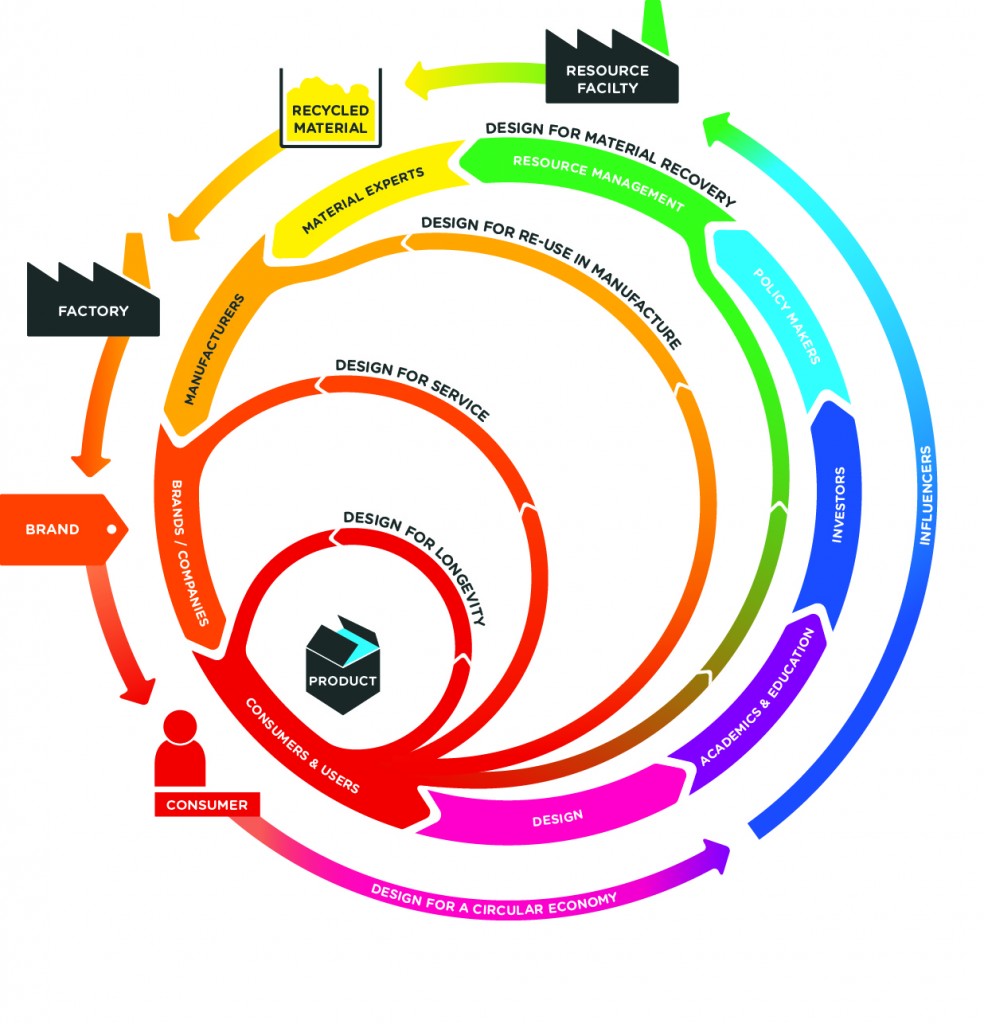

The Great Recovery’s Four Design Models diagram is a practical tool for re-thinking and re-designing products and services for a more circular economy:

- Design for longevity

This is the way we used to design things: for long life and fixability. Products can be easily taken apart for upgrade or repair, and are well crafted and reliable. Users place high levels of trust in these products and are emotionally attached to them, increasing the likelihood that they value them for a long time and then pass them on to another owner rather than throwing them away.

- Design for leasing or service

The product-sharing business model is becoming more common as leasing is seen as an alternative to ownership. It allows for higher specifications of design and materials that increase life and durability. The material stays in the ownership of the manufacturer as the product is never sold, so value is kept within the system.

- Design for re-use in manufacture

These business models and systems support the return of old products to manufacturers so that they can upgrade or replace components, fix and resell them. Reverse supply chains and effective legislation are important factors in remanufacturing. These products need to be designed for easy factory disassembly in order to increase their material utilisation.

- Design for material recovery

Products in this outer loop can be reprocessed – recycled – into new materials. These procedures can involve intensive recovery methods that extract the most value currently available. Design for fast-flowing product streams such as packaging must work effectively with the recovery industry to increase the value of material recovered and to reduce contamination and multi-material complexity.

Some of the things we considered for the brief were: local manufacture, long life in-use, recycled and recyclable materials, and eliminating waste.

We then had to choose what product we would redesign (or design from scratch, as a simple redesign would not be enough). There are millions of options and examples of bad product design, so it was a hard choice. We wanted something that just had one function (for example, cleaning teeth), a low value/ high volume product, and that had quite a short life – meaning it would end up in landfill soon after it’s manufactured. We wanted to rethink and redesign a product which typically has a linear lifecycle, and which people don’t give a second thought to before throwing away.

Design for a linear system is the most common method of product design, although it is changing little by little as sustainability becomes more important in the design world, and is being taught in universities and some schools. In our case, we wanted to design the product to go against this common methodology,

and follow a more circular pattern.

There are different strategies to design different products, and there is no one-way of designing a product for circularity, as demonstrated by the 4 Design Models diagram. In this project we will try and follow each of the paths to create different solutions or concepts for each, which could then be combined to make one or more final products.

Our project will revolve around disposable razors, to design a solution which won’t go into landfill at the end of its life. A full explanation of this choice will be shown in the next post in the series.

Even during this really early stage of the process we’ve already found some problems:

- People have different opinions on what sustainability is – is it circularity? Cradle to cradle? Energy use?

- Making a product sustainable is too broad, the brief has to be narrowed down so it can be carried out – you can’t work on solving every problem at once (further iterations could concentrate on improving other problem areas)

This project is a collaboration between the Great Recovery Programme and Fab Lab London.